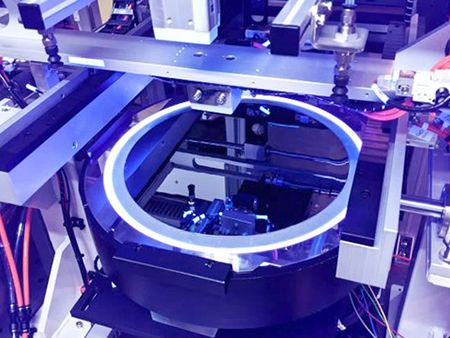

Wafer Metal Frame Tape Disassembly Equipment

Automatic Wafer Ring Film Disassembly Equipment

The iron wafer frame is mainly used in wafer dicing to fix the outer frame during wafer grinding and cutting, and the frame can be recycled and cleaned repeatedly. The equipment can automatically remove the film for the wafer iron frame, and features the functions of detecting residual wafer, cleaning residual glue and bagging the iron frame automatically.

Features

- Using dry cleaning, effectively remove glue residue.

- Automatic optical residual grain detection.

- Support SECS/GEM communication.

Applications

Iron Wafer Frame (with blue film)

Specification

- Wafer Size: 8", 12", or both

- Wafer Ring Warpage ≤ 1mm

- Film Deformation ≤ 10mm

- UPH > 100

| No. | Item | Criteria | |

|---|---|---|---|

| 1.1 | Working Capacity | Feeding Specification | 12" Wafer ring |

| 1.2 | Wafer frame Cassette 方式入料 | ||

| 1.3 | Allowable Product Deformation | Wafer ring Warpage ≤ 1mm | |

| 1.4 | Film deformation ≤ 10mm | ||

| 2.1 | Load Port | Cassette | 1. 2 Cassette load. 2. Cassette payload max: Weight 20Kg |

| 2.2 | During Cassette operation, the safety door must not be opened. (Specify Omron safety switch) | ||

| 2.3 | Cassette anti-drop ring is not opened, the machine must be alarmed and cannot be operated. | ||

| 2.4 | Cassette is not positioned, the machine must alarm and stop working. | ||

| 2.5 | Cassette presence detection function, detect no cassette machine alarm and stop operation. | ||

| 2.6 | Wafer Ring Protrusion detection, or anti-fooling mechanism to prevent protrusions from colliding with materials. | ||

| 2.7 | Wafer Ring double / cross slot / position / quantity check function, and displayed on the operation interface. | ||

| 2.8 | Wafer Ring Arm | 1. Wafer Ring Arm has Wafer Ring unclamp detection. 2. Arm over-push / pull protection mechanism, Push value ≥ 2kgf Alarm. | |

| 2.9 | 1. Suction failure vacuum detection. 2. The vacuum in the factory facility can be supply for more than 3 minutes, and the product can be placed in a safe place during the period, without any doubts about chip falling. 3. When the power is cut off, the equipment cannot operate, but the pressure can be maintained continuously, and there is no doubt about chip dropping. | ||

| 2.10 | E84 | E84 reserved E84 function upgrade. | |

| 2.11 | Ring ID | Reader | Ring ID Reader read Wafer ring 1D barcode. |

| 3.1 | Metal Frame / Tape Film Separation | Transfer Arm | vacuum detection of suction failure. |

| 3.2 | Detection of tape film placement failure (sticking to transfer Arm). | ||

| 3.3 | Tape Film Blanking Area | 1. Placed in a stacked manner, the stacking Max height is 60mm. 2. There are 2 stacking areas. 3. The presence detection in the stacking area must have the function of automatic batch change and anti-mixing. | |

| 3.4 | Separator paper placement function. | ||

| 3.5 | Separator paper storage tank replenishment detection function. | ||

| 3.6 | Metal Frame Blanking Area | 1. Placed in a stacked manner, the stacking Max. height is 150mm. 2. Stack full detection. | |

| 4.1 | Machine Whole Area | Status Detection | Alarm when the event of a mechanism transfer failure or failure to locate during the operation. |

| 4.2 | Security Mechanism Function | It is forbidden to open all the door and machine cover during the operation. | |

- Gallery

Wafer Metal Frame Tape Disassembly Equipment | Made in Taiwan Intelligent Process Equipment | Shuz Tung

Based in Taiwan since 1979, Shuz Tung Machinery Industrial Co., Ltd. is a manufacturer of intelligent process equipment. It's main intelligent process equipment include, Wafer Metal Frame Tape Disassembly Equipment, semiconductor automation equipment, semiconductor metrology and inspection equipment, flat panel display turnkey equipment, TFT-LCD module process whole line equipment and wafer shipper automatic packing and unpacking machines. We offer customized designs for optimal equipment efficiency in high-tech industries. Prioritizing speed of production, quality and environmental friendliness ensures competitive advantage and significant added value.

Established in 1979, with 43 years vast experience and resources in customized equipment manufacturing, and outstanding optical, mechanical, electronic, software, and system integration ability, Shuz Tung Machinery Industrial focuses on the core technologies, including Precision Mold Manufacturing, Laser Repair and Cutting, High Accuracy Bonding (PCB Bonder), Automatic Optical Inspection (AOI), Artificial Intelligence Imaging, and Turnkey Solution for Smart Manufacturing.

Shuz Tung has been providing customers with high quality intelligent process equipment since 1979, both with advanced technology and 30 years of experience, Shuz Tung ensures that each customer's needs are met.