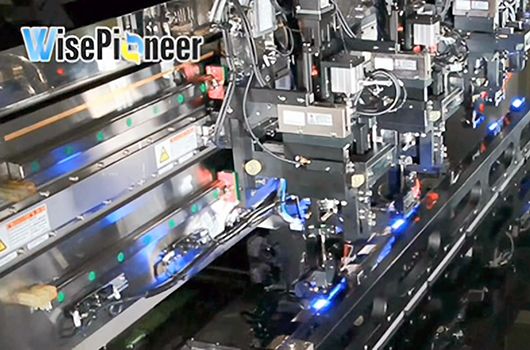

Application of High-Precision Bonding Technology

PCB Bonding, OLB Bonding (Outer Lead Bonder), Lamination

Shuz Tung Machinery possesses the integrated technology of optical, mechanical, and electrical systems. Its core technologies cover automated plant integration, high-precision bonding, automatic optical inspection, AI recognition software, laser repair and cutting, and precision mold manufacturing. By transitioning from automated equipment to process equipment, Shuz Tung Machinery further plans for customers' plant automation and intelligent manufacturing services.

Shuz Tung's high-precision bonding technology achieves electrical connections by using precise temperature and pressure control to thermally bond the circuits on the driver circuit board (PCB) or Chip On Film (COF) to those on the panel, and it also has the ability to produce various sizes (4-110 inches) and shapes of products. This advanced and mature technology includes the attachment of anisotropic conductive film (ACF), pre-bonding, and main-bonding, providing high-precision (OLB: X ± 3um; Y ± 20um; θ ± 0.05) and high-efficiency production equipment.

The global automotive panel continues to innovate by combining deep consumer electronics display technologies, such as irregular cutting and large-sized bonding, to comprehensively expand in-cabin automotive display applications. Shuz Tung integrates automotive displays and human-machine interfaces to develop smart cabin systems, enabling future applications of automotive panels beyond imagination. The narrow-border hot-press bonding technology can increase the flexibility of terminal product mechanism design, making the appearance more fashionable.