R&D Achievements

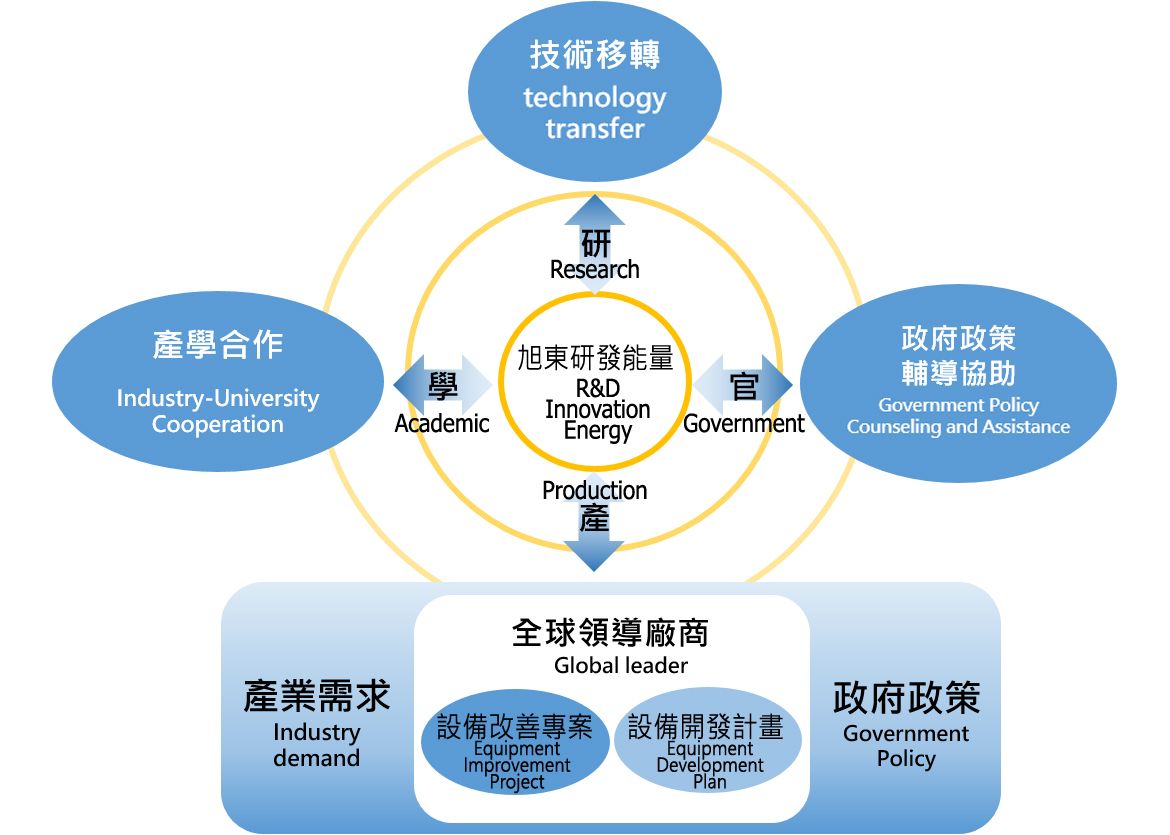

Shuz Tung Machinery has established three research and development centers globally, and takes Taiwan as the center of its technology research and development. Through deep cultivation of core foundational technologies such as optics, mechanics, electronics, software, and processes, Shuz Tung Machinery continues to integrate external resources from industry, academia, and research institutions to develop technologies and products that meet market demand. The company also cultivates its own R&D talent and continuously enhances its capabilities in key equipment R&D.

The research and development achievements of Shuz Tung Machinery's Electronic Equipment Department are as follows:

| Technology | Achievement |

|---|---|

| Key Differential Interference Optical Module Design Technology | Microscope module, differential interference module, spectroscopic module, polarization module, CCD image processing module, light source module and uniform light module are connected in series. Develop localized key differential interference optical modules to present 3D images with good shading effects on the image sensor to meet the production line needs of customers' key processes. |

| High Speed and High Dynamic Electromechanical Design Technology | Integrate high-standard electromechanical system technology to achieve high-speed and high-dynamic movement control and high-precision motion control capabilities, and establish laser focus tracking system technology to overcome factors that affect equipment stability through high-stability and high-dynamic real-time focus tracking capabilities. To overcome the problem that the warpage becomes larger in the production process of ultra-thin products and affects the production process. |

| Advanced Multi-Functional System Integration Technology | Develop functions such as process parameter management, testing software, product production information management, machine status management, and user-friendly customized interface design to improve equipment service capabilities and meet the needs of the industry's most advanced fully automatic production line process yield control. |

| Laser Direct Imaging Technology | Develop an LDI System for the PCB industry to meet the future demands of small-volume and diversified customers, while providing reliable and cost-effective manufacturing equipment with innovative production capabilities. |

| High-speed Imaging Technology Transfer, High-Speed Detection Technology Transfer, Algorithm Technology Transfer, DSP FPGA Technology Transfer, Process Technology Support. | The high-speed AOI detection technology that is lacking domestically has taken root in Taiwan. In conjunction with our company's equipment manufacturing and service system, we will localize the ADI / AEI inspection equipment to reduce dependence on imported equipment and increase the competitiveness of the domestic panel industry. |

| Automatic Optical Inspection Defect Classification Technology Development | It can fully comply with the requirements of panel manufacturers to continuously improve the accuracy of ADC, and meet the demand for domestication of future new-generation photonic industry inspection equipment. |

| Application for the Development of Substrate Bonding Equipment Technology. | After the completion of this technology development, it will have complete technical independence, avoiding control of panel equipment by competing manufacturers in Japan and South Korea. Our company's automated equipment product line will be more comprehensive, meeting the concept of Multi-Function Machine proposed by current panel manufacturers, effectively reducing industry equipment costs and enhancing competitiveness. |