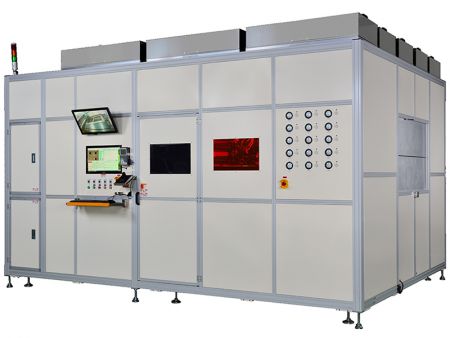

Mask Laser Repair

AOI + Laser Repair

Mask Laser Repair Inspection machine and laser machine (AOI + Laser Repair) for metal mask inspection and repair. The equipment structure includes XYZ motion axes, CCD cameras, control computers, laser heads, and other devices.

Features

1. The laser device, controlled by an aperture and energy control device that regulates the size and energy of the XY beam, provides optimal energy for processing touch panels through the lens assembly.

2. The laser processing area is aided by enhanced white lines, allowing the shape of the laser beam to be displayed on the screen.

3. Operators can use the mouse to control the size of the laser guide wire and move the processing position, thus controlling the laser processing area.

4. The laser machine can be connected and controlled through USB data or local area network, allowing integration with upstream inspection machines. The CCD on this device can identify defect locations for subsequent processing.

5. The laser equipment is designed in accordance with "JIS C6802: Laser Safety" Class 1 standards and complies with CE standards under 98/37/EC, 73/23/EEC, and 89/336/EEC directives.

Application Scope

- Size: 580mm x 850mm

- Weight: 22.6kg

Product Accuracy and Capacity

- Lens: 640MHz 8K pixels x 1

- Scan Rate: 68K Line/sec

- Light Source: Coaxial Light + Backlight + Sidelight

- Physical Resolution: 3.5 μm (detecting defects of 7 μm or above)

- Field of View: 24mm

Features

- Customized integrated new development design for full-size LCD module panels.

- Integrated real-time inspection and laser repair functions, achieving optimal efficiency in repair synchronization.

- Possesses high precision defect handling capabilities.

- User-friendly and intuitive operation interface.

Applications

1. Effectively remove surface particles / residues on SHEET without damaging the substrate.

2. Can be combined with ultrasonic cleaning.

3. Can be combined with AOI scanning.

Mask Laser Repair | Made in Taiwan Intelligent Process Equipment | Shuz Tung

Based in Taiwan since 1979, Shuz Tung Machinery Industrial Co., Ltd. is a manufacturer of intelligent process equipment. It's main intelligent process equipment include, Mask Laser Repair, semiconductor automation equipment, semiconductor metrology and inspection equipment, flat panel display turnkey equipment, TFT-LCD module process whole line equipment and wafer shipper automatic packing and unpacking machines. We offer customized designs for optimal equipment efficiency in high-tech industries. Prioritizing speed of production, quality and environmental friendliness ensures competitive advantage and significant added value.

Established in 1979, with 43 years vast experience and resources in customized equipment manufacturing, and outstanding optical, mechanical, electronic, software, and system integration ability, Shuz Tung Machinery Industrial focuses on the core technologies, including Precision Mold Manufacturing, Laser Repair and Cutting, High Accuracy Bonding (PCB Bonder), Automatic Optical Inspection (AOI), Artificial Intelligence Imaging, and Turnkey Solution for Smart Manufacturing.

Shuz Tung has been providing customers with high quality intelligent process equipment since 1979, both with advanced technology and 30 years of experience, Shuz Tung ensures that each customer's needs are met.