Automatic Wafer FOUP / FOSB Inspection Equipment

WF-3000

Automatic Wafer Inspection

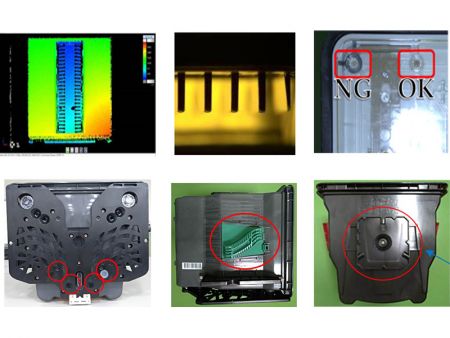

Automatic wafer cassette (FOUP / FOSB) inspection equipment is used in the semiconductor manufacturing process to inspect the appearance defects, missing parts and deformation of the wafer cassette due to friction and collision during the transfer process, reduce the risk of wafer contamination due to wafer cassette defects.

Features

- Fully automated non-contact optical inspection.

- Customizable testing items.

- Conforms to SEMI S2 certification.

- Support SECS / GEM communication.

Specification

- UPH ≥ 17

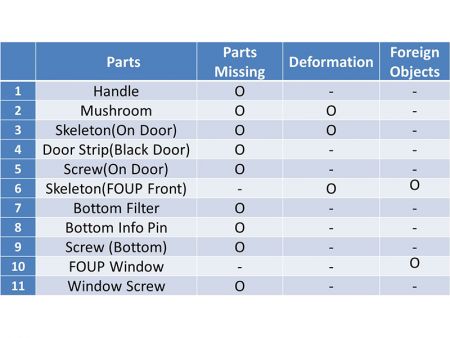

- Inspection Items: Wafer Cassette handle, mushroom head, row frame (on the door), door panel rubber strip, screw (on the door), row frame (front), bottom filter, bottom Info Pin, screw (bottom), FOUP Window, window screws, FOUP wings, door panel keyholes, and other barcode comparisons, door panel warping, door panels not fully closed...etc.

- Equipment Size: 2800mm (L) x 1900mm (W) x 2200mm (H)

- Gallery

Automatic Wafer FOUP / FOSB Inspection Equipment | Made in Taiwan Intelligent Process Equipment | Shuz Tung

Based in Taiwan since 1979, Shuz Tung Machinery Industrial Co., Ltd. is a manufacturer of intelligent process equipment. It's main intelligent process equipment include, Automatic Wafer FOUP / FOSB Inspection Equipment, semiconductor automation equipment, semiconductor metrology and inspection equipment, flat panel display turnkey equipment, TFT-LCD module process whole line equipment and wafer shipper automatic packing and unpacking machines. We offer customized designs for optimal equipment efficiency in high-tech industries. Prioritizing speed of production, quality and environmental friendliness ensures competitive advantage and significant added value.

Established in 1979, with 43 years vast experience and resources in customized equipment manufacturing, and outstanding optical, mechanical, electronic, software, and system integration ability, Shuz Tung Machinery Industrial focuses on the core technologies, including Precision Mold Manufacturing, Laser Repair and Cutting, High Accuracy Bonding (PCB Bonder), Automatic Optical Inspection (AOI), Artificial Intelligence Imaging, and Turnkey Solution for Smart Manufacturing.

Shuz Tung has been providing customers with high quality intelligent process equipment since 1979, both with advanced technology and 30 years of experience, Shuz Tung ensures that each customer's needs are met.