Automatic IC Tray Packing Equipment

SPT

Automatic IC Packing Equipment

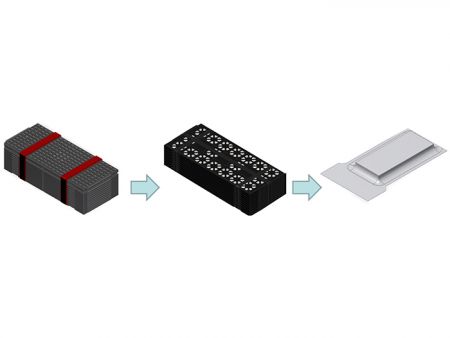

Automatic IC Tray Packing is applied to the semiconductor packaging and testing industry. Automatic IC Tray packaging before IC shipment to the client, to save labor cost and achieve packaging process monitoring and controlling, to ensure product quality. This equipment is used to automatically remove the polyester strapping, remove the ID card, put the label card on the Tray, tie the tape according to the setting, put the desiccant packet and humidity card into the antistatic bag for vacuum sealing.

Features

- Corresponding to more than four types of packaging bags, humidity cards, desiccant packets, and label printing requirements.

- Automatic placement of desiccant packet, automatic strapping, vacuum heat sealing, and automatic labeling.

- Trolley feeding is applicable.

- Automatic belt stripping machine.

- Vacuum cavity type seal.

- On-power feeding.

Applications

Semiconductor wafer manufacturing, packaging, testing and related industry.

Specification

- UPH ≥ 65

- Tact Time (T/T): 55 sec

- Applicable Carrier: Tray

- Dry Bag Storage: 152

- HIC Card Slot: 120 tablets

- Gallery

Automatic IC Tray Packing Equipment | Made in Taiwan Intelligent Process Equipment | Shuz Tung

Based in Taiwan since 1979, Shuz Tung Machinery Industrial Co., Ltd. is a manufacturer of intelligent process equipment. It's main intelligent process equipment include, Automatic IC Tray Packing Equipment, semiconductor automation equipment, semiconductor metrology and inspection equipment, flat panel display turnkey equipment, TFT-LCD module process whole line equipment and wafer shipper automatic packing and unpacking machines. We offer customized designs for optimal equipment efficiency in high-tech industries. Prioritizing speed of production, quality and environmental friendliness ensures competitive advantage and significant added value.

Established in 1979, with 43 years vast experience and resources in customized equipment manufacturing, and outstanding optical, mechanical, electronic, software, and system integration ability, Shuz Tung Machinery Industrial focuses on the core technologies, including Precision Mold Manufacturing, Laser Repair and Cutting, High Accuracy Bonding (PCB Bonder), Automatic Optical Inspection (AOI), Artificial Intelligence Imaging, and Turnkey Solution for Smart Manufacturing.

Shuz Tung has been providing customers with high quality intelligent process equipment since 1979, both with advanced technology and 30 years of experience, Shuz Tung ensures that each customer's needs are met.